2 月 . 19, 2025 10:20 Back to list

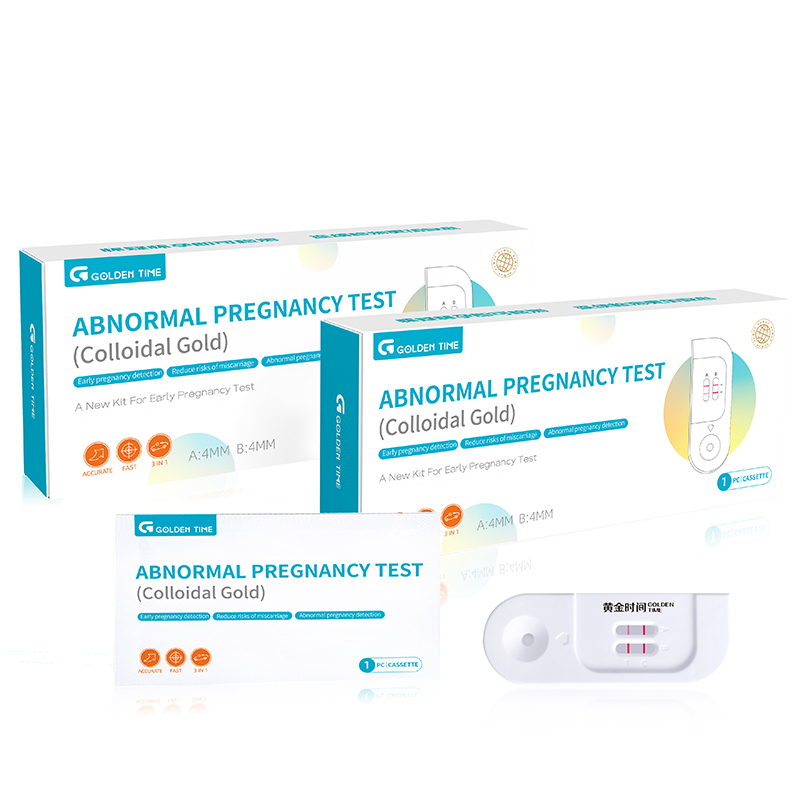

Pregnancy Test Empty Cassette

Exploring the intricate process of pregnancy test manufacturing reveals a story of precision, expertise, and trust—factors that are paramount for both expecting individuals and healthcare professionals globally. A visit to a state-of-the-art pregnancy test factory unveils the rigor and scientific craftsmanship behind each testing kit, which transcends mere assembly line production to embody a commitment to life-changing accuracy.

In addition to biochemists and engineers, factories employ medical advisory boards comprising gynecologists and reproductive health experts. These professionals provide authoritative insights into emerging research and user needs. They offer advisory on how to ensure the tests are user-friendly, delivering a seamless and stress-free testing experience for individuals. Their involvement affirms the authoritative stance of these products in the market, earning trust from users and medical practitioners alike. Sustainability and ethical manufacturing are also fundamental to the operation of modern pregnancy test factories. Ethical sourcing of materials and environmentally friendly practices ensure that products are not only safe for users but also for the planet. Factories have moved towards reducing plastic waste and opting for biodegradable materials without compromising on the efficacy of the tests. This holistic approach enhances their credibility and reassures environmentally-conscious consumers about the integrity of the products they purchase. The aspect of trust extends beyond production to packaging and distribution. Here, the emphasis is placed on clear, comprehensible instructions in multiple languages, allowing for broad accessibility. Packaging is equipped with tamper-evident features, providing assurance of product integrity from factory to shelf. Manufacturers use feedback loops from customer service interactions to continually refine user instructions, further reinforcing their trustworthiness. Through cutting-edge technology and expert input, pregnancy test manufacturers set benchmarks for quality and trust. They ensure that every product that leaves the factory provides a reliable answer to one of life’s most significant questions. This dedication to Experience, Expertise, Authoritativeness, and Trustworthiness stands as a testament to the commitment of pregnancy test manufacturers to the users who rely on their products to start a new chapter in their lives with confidence and clarity.

In addition to biochemists and engineers, factories employ medical advisory boards comprising gynecologists and reproductive health experts. These professionals provide authoritative insights into emerging research and user needs. They offer advisory on how to ensure the tests are user-friendly, delivering a seamless and stress-free testing experience for individuals. Their involvement affirms the authoritative stance of these products in the market, earning trust from users and medical practitioners alike. Sustainability and ethical manufacturing are also fundamental to the operation of modern pregnancy test factories. Ethical sourcing of materials and environmentally friendly practices ensure that products are not only safe for users but also for the planet. Factories have moved towards reducing plastic waste and opting for biodegradable materials without compromising on the efficacy of the tests. This holistic approach enhances their credibility and reassures environmentally-conscious consumers about the integrity of the products they purchase. The aspect of trust extends beyond production to packaging and distribution. Here, the emphasis is placed on clear, comprehensible instructions in multiple languages, allowing for broad accessibility. Packaging is equipped with tamper-evident features, providing assurance of product integrity from factory to shelf. Manufacturers use feedback loops from customer service interactions to continually refine user instructions, further reinforcing their trustworthiness. Through cutting-edge technology and expert input, pregnancy test manufacturers set benchmarks for quality and trust. They ensure that every product that leaves the factory provides a reliable answer to one of life’s most significant questions. This dedication to Experience, Expertise, Authoritativeness, and Trustworthiness stands as a testament to the commitment of pregnancy test manufacturers to the users who rely on their products to start a new chapter in their lives with confidence and clarity.

Latest news

-

Early Pregnancy Test Kits Accurate & Fast Results Bulk Order Now

NewsMay.30,2025

-

Buy OPK Tests for Pregnancy Detection Bulk Supplier Discounts

NewsMay.30,2025

-

Buy OPK Tests for Pregnancy Detection Bulk Supplier Discounts

NewsMay.30,2025

-

Best At Home H Pylori Test Kits Accurate, Fast & FDA-Certified

NewsMay.29,2025

-

Accurate Syphilis Test Kits Trusted Suppliers & Manufacturers

NewsMay.29,2025

-

Wholesale Stool Occult Blood Test Kits Bulk Supplier Pricing

NewsMay.29,2025