12 月 . 03, 2024 18:52 Back to list

typhoid rapid test factory

The Importance of Typhoid Rapid Test Factories

Typhoid fever, caused by the bacterium Salmonella typhi, remains a significant public health challenge in many developing countries. It is transmitted through contaminated food and water, and its symptoms can lead to severe complications if not treated promptly. With over 21 million cases reported annually, the need for accurate and swift diagnostics is critical. This is where typhoid rapid test factories play a pivotal role in the healthcare landscape.

The Need for Rapid Testing

In areas where typhoid fever is endemic, traditional laboratory testing methods, such as blood cultures, can be time-consuming and require specialized equipment and trained personnel. These resources may not always be available in remote regions where the disease is most prevalent. Rapid diagnostic tests (RDTs) enable healthcare providers to quickly identify infections, leading to timely treatment and reducing the spread of the disease.

Rapid tests for typhoid fever typically utilize immunochromatographic assay techniques, which allow for the detection of specific antibodies or antigens related to Salmonella typhi in a patient's sample. These tests are designed to provide results within 15 to 30 minutes, empowering healthcare workers to make immediate clinical decisions.

The Role of Typhoid Rapid Test Factories

Typhoid rapid test factories are essential for the production and distribution of these critical diagnostic tools. These factories focus on developing high-quality, accurate, and cost-effective testing kits that can withstand the rigors of distribution in challenging environments. The factory processes encompass several key stages, including research and development, quality assurance, manufacturing, and logistics.

1. Research and Development This stage involves the exploration of various detection methodologies and the optimization of test sensitivity and specificity. Collaborative efforts with universities and research institutions can lead to innovative solutions that enhance test performance.

typhoid rapid test factory

2. Quality Assurance Rigorous testing and validation protocols are crucial in ensuring that rapid tests meet international standards. Factories must adhere to regulatory guidelines set forth by health authorities, such as the World Health Organization (WHO) and the U.S. Food and Drug Administration (FDA). Quality control measures during manufacturing guarantee that each batch of tests is reliable.

3. Manufacturing Utilizing state-of-the-art technology and efficient workflows, manufacturing facilities can produce large volumes of test kits. Automation plays a vital role in enhancing productivity while minimizing potential human errors. Factories are designed to optimize space and resources to ensure that production levels can meet emergency demands.

4. Logistics and Distribution Once produced, rapid test kits must be effectively distributed to healthcare providers in endemic areas. This requires a robust supply chain strategy, often leveraging partnerships with non-governmental organizations (NGOs) and international health agencies. Cold chain logistics may be necessary to maintain the integrity of some test components, ensuring they remain effective until they reach the end user.

Impact on Public Health

By significantly reducing the time required to diagnose typhoid fever, rapid tests produced in these factories can help reduce mortality rates and improve health outcomes. Quick diagnosis enables healthcare professionals to initiate appropriate antibiotic therapy faster, which is crucial in managing the infection and preventing severe complications, such as intestinal perforation.

Moreover, widespread availability of these tests can facilitate community health initiatives, enabling early detection and reporting of outbreaks. This information is vital for public health officials to implement control measures and allocate resources efficiently.

Conclusion

In conclusion, typhoid rapid test factories represent an innovative and essential response to a longstanding public health challenge. By developing high-quality rapid tests, these factories can improve diagnostic capabilities in regions most affected by typhoid fever, ultimately leading to better patient outcomes. Continued investment in production capabilities, research, and partnerships will help combat this disease effectively and save countless lives in the process. As global health organizations strive for a world free of preventable diseases, the role of rapid test factories for typhoid fever will undoubtedly remain a cornerstone of these efforts.

-

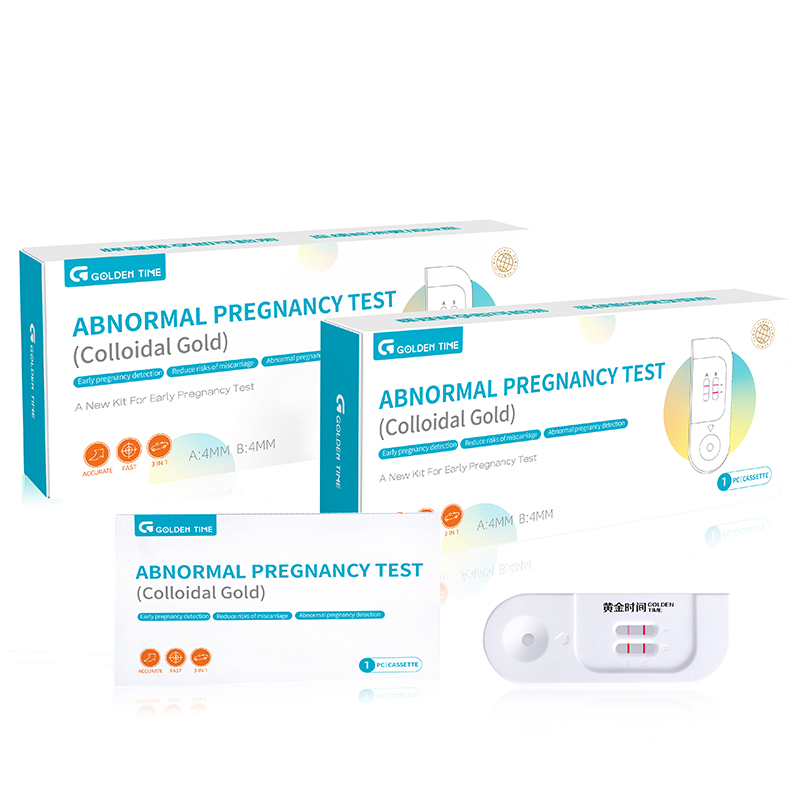

Early Pregnancy Test Kits Accurate & Fast Results Bulk Order Now

NewsMay.30,2025

-

Buy OPK Tests for Pregnancy Detection Bulk Supplier Discounts

NewsMay.30,2025

-

Buy OPK Tests for Pregnancy Detection Bulk Supplier Discounts

NewsMay.30,2025

-

Best At Home H Pylori Test Kits Accurate, Fast & FDA-Certified

NewsMay.29,2025

-

Accurate Syphilis Test Kits Trusted Suppliers & Manufacturers

NewsMay.29,2025

-

Wholesale Stool Occult Blood Test Kits Bulk Supplier Pricing

NewsMay.29,2025